CableFree 5G: Smart Manufacturing & Factory Automation, Industry 4.0

Introduction

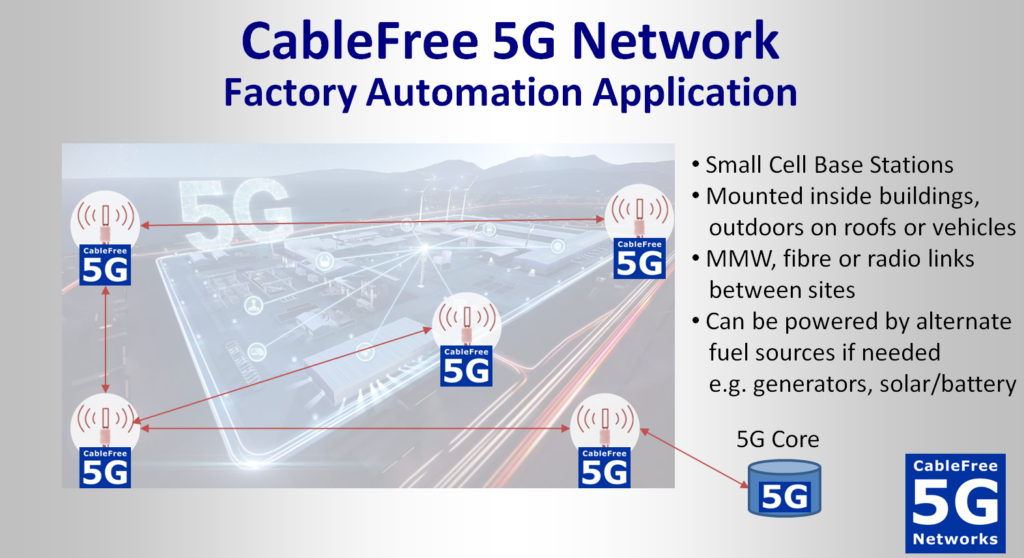

Factory automation is a key driver of increased efficiency, productivity, and cost-effectiveness in modern smart manufacturing environments and Industry 4.0. To achieve seamless and reliable connectivity in these environments, traditional solutions like Wi-Fi and fiber optic cables have been widely used. However, emerging technologies, such as CableFree 5G Small Cell Radios, offer significant advantages in terms of capacity, coverage, and cost-effectiveness for factory automation.

This application note explores how CableFree 5G Small Cell Radios can enhance factory automation compared to Wi-Fi and fiber optic cables, highlighting the benefits they bring to capacity, coverage, and cost.

1. Capacity Benefits for Factory Automation

a. High Bandwidth

CableFree 5G Small Cell Radios provide a substantial increase in bandwidth compared to traditional Wi-Fi networks. This higher bandwidth enables real-time data transfer and supports applications such as robotic control, high-definition video monitoring, and augmented reality (AR) tools, which are crucial for modern factory automation.

b. Low Latency

5G technology offers extremely low latency, often less than 11 milliseconds. This near-instantaneous response time is vital for applications that require split-second decisions, like autonomous robots and remote machine control, improving overall factory efficiency.

c. Network Slicing

5G networks support network slicing, allowing factories to dedicate specific network slices to different types of applications. This ensures that critical control systems have the necessary bandwidth and prioritization, preventing interference or congestion from less critical applications.

2. Coverage Benefits for Smart Manufacturing

a. Wide Coverage Area

CableFree 5G Small Cell Radios provide extensive coverage, both indoors and outdoors, thanks to their compact size and scalability. This means fewer infrastructure components are required, reducing the overall complexity of the network.

b. Robust Connectivity

5G networks are less susceptible to interference from physical obstacles and electromagnetic interference, making them more reliable in challenging factory environments with machinery, metal structures, and high interference potential.

c. Mobile Connectivity

Factory automation often involves mobile robots or handheld devices. 5G’s seamless handover capabilities ensure that these devices maintain connectivity even when moving throughout the facility, reducing downtime and increasing productivity.

3. Cost Benefits for Industry 4.0

a. Reduced Infrastructure Costs

Compared to deploying extensive fiber optic cable networks, installing CableFree 5G Small Cell Radios is more cost-effective. It eliminates the need for costly trenching, cabling, and maintenance associated with traditional wired networks.

b. Scalability

5G networks are highly scalable. Factories can start with a small deployment and expand as needed, without significant additional infrastructure costs. This scalability aligns with the dynamic nature of manufacturing environments.

c. Lower Operating Costs

The reliability and low latency of 5G networks reduce operational costs by minimizing downtime, maintenance, and troubleshooting efforts. Energy-efficient small cell radios also contribute to reduced power consumption compared to large Wi-Fi access points.

Comparison with WiFi

While WiFi remains a common choice for providing internet access in factory and manufacturing locations, CableFree 5G radios offer distinct advantages:

- Capacity: CableFree 5G radios provide significantly higher capacity, reducing the risk of network congestion during peak usage times.

- Coverage: 5G radios cover a more extensive area, ensuring that guests throughout the park or site can access a reliable connection.

- Interference: WiFi networks are susceptible to interference from neighboring networks, while 5G radios operate in dedicated frequency bands, minimizing interference.

- Scalability: Scaling WiFi networks can be complex and costly, whereas CableFree 5G radios offer straightforward scalability.

Conclusion: 5G for Factory Automation

CableFree 5G Small Cell Radios offer substantial benefits for factory automation compared to traditional Wi-Fi and fiber optic cable solutions. Their capacity advantages, extensive coverage, and cost-effectiveness make them a compelling choice for manufacturers seeking to improve efficiency, productivity, and overall operational performance.

By embracing CableFree 5G Small Cell Radios, factories can create more agile, responsive, and cost-efficient automation systems that are well-equipped to meet the demands of modern manufacturing environments.

Proven Wireless Performance Worldwide

CableFree Wireless products are field-proven, with thousands of deployments in over 80 countries since 1996. Excellence in performance and reliability are ensured providing highly competitive solutions together with a comprehensive range of support services.

Request More Information

For More Information on CableFree Wireless Networking Products, please Contact Us and our team will be delighted to advise on a precise solution to match your exact requirements.

You must be logged in to post a comment.